The following article was first published in the Bulletin of the Historical Harp Society, March 2010, and was written some months before the documentary Banríon an Cheoil first broadcast (3rd May 2010). Reproducing the article here has given the author the opportunity to expand on the previously published work. This mainly takes the form of adding a number of detailed footnotes and references plus the inclusion of an Appendix which was not completed in time to meet the Bulletin's deadline. The text now also includes some further dimensional information and a few more photographs and illustrations.

FIGURE 1. Engraving of Hempson playing the harp, from a drawing by E. Scriven made in 1797 (reproduced from Edward Bunting’s The Ancient Music of Ireland (1840.)

If you came here from the Survey section below,On the 11th, 12th, and 13th July 1792, a gathering was held of “the last of the Irish harpers” in the Assembly Rooms, Waring Street, Belfast. The organisers made the occasion even more historic by engaging a young and talented musician to note down and preserve the old harpers’ music before it died with them; thus did 19–year–old Edward Bunting inscribe his name indelibly into the history of Irish music. Over the years that followed, he continued to collect music and other information from the fast–disappearing harpers, and he would go on to publish three influential volumes of this material, in 1796, 1809, and 1840. Through these, together with his papers preserved in the Library of Queen’s University Belfast, Bunting provides some of the most important reference works on the old harp of Ireland (though one must always strive to look beyond any single source and seek the fullest picture, particularly where the evidence is anecdotal).[1]

Of the ten Irish harpers that attended the gathering, one in particular caught Bunting’s ear. Denis Hempson was approaching one hundred years of age at the time of the meeting and it is not surprising that Bunting found in his repertoire some of the oldest of the music. Bunting was also fascinated by the fact that Hempson—unlike all the others—played the harp with fingernails.

“Denis Hempson” is the form in which his name is most often encountered, but he was also called O’Hampsey and Hampson, and in Irish, Donncha Ó h Ámhsaigh.[2] Most of what is known about him comes from Bunting and from a letter written by the Rev. G. Sampson, following a visit to the old harper in 1805.[3] Except for a few omitted lines, this entire letter was reprinted in Bunting’s 1840 work.[4] I do not intend to give much of Hempson’s life story here except to say that he was born near Garvagh, Co. Derry, in 1695 (according to Bunting),[5] was blinded by smallpox at age three, started learning the harp when he was twelve, and began his playing career at eighteen. He died in 1807 at Magilligan, Co. Derry, and throughout his long playing life his instrument was the Downhill Harp.

In a famous depiction (Figure 1) Hempson is shown pulling the treble strings of his harp with the left hand (the usual Irish practice of the time) and it also offers an insight into his playing position. It has often been commented that the old Irish harpers held the instrument on the left shoulder, but that’s not quite accurate in this case. Hempson can clearly be seen resting his chin on the top of the harp’s neck, against the terminus of the ridge decoration. This position would have allowed his feet to support the two bottom corners of the soundbox while his head clamped down on a fixed location at the top of the curve, bracing the harp securely; and it would give the blind musician a fixed point of reference for muscle memory. In addition, the wood being in physical contact with his jaw would mean the music not only was audible but also resonated through the bone.

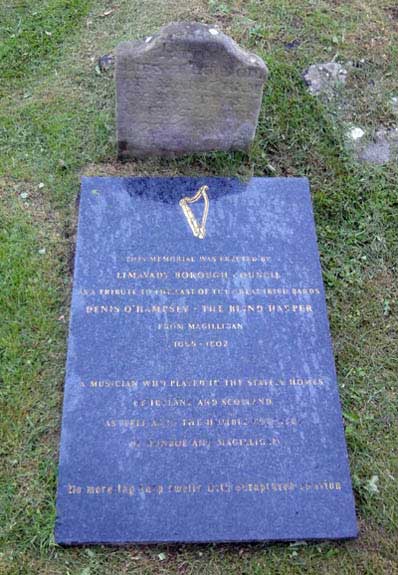

The Memorial Stone in the graveyard of St. Aidan’s Church, Co. Derry, where Denis Ó Hampsey (Denis Hempson) lies buried.

(Photo ©2010 by Michael Billinge, used by permission.)

[You may click on the picture to view a larger–sized image]

Sitting in this manner offered Hempson one other advantage as well. Owing to a large growth on the back of his skull, he was widely known as “the man with two heads” [6] and even Bunting—who was an admirer—referred to him as “Mr. Purty Ugly” [7] in his notebook when jotting down a tune attribution, another of poor Hempson’s nicknames. One can only wonder what this blind man made of being mocked for a defect that offended the sight of others, which he could not himself comprehend.

A careful look at the picture shows that his hat is not actually placed on his head but perched a few inches above it and tipped forward by the wen. A protuberance of this size added weight to his century—old neck and shoulders, so being able to use the harp to rest upon would have given some relief from the burden.

In 2008 I was asked to participate in a television documentary about the old Irish wire–strung harp, taking as its central subject Denis Hempson’s instrument, the Downhill Harp. This is being presented jointly by the Irish–language station TG4 (Teilifis Gaeilge) and BBC2 Northern Ireland, and much of the spoken commentary will be in Irish (with subtitles), though a number of people interviewed use English.

The programme explores the making of a replica of the Downhill Harp, as well as aspects of playing wire–strung harp, and the project culminated in a grand concert where ten wire–strung harpers from various countries met and performed in celebration of the 1792 gathering and its original musicians, which numbered ten Irish participants and one Welshman, who sadly died shortly afterwards. [WireStrungharp.com hosts a review of this concert.]

After 217 years, wire-strung harps are heard again in the Assembly Rooms in Belfast: Bill, Nollaig, and Bonnie at the start of the lunchtime recital.

Photo ©2009 by Michael Billinge, used by permission.

The production will see the presenter, Nollaig Brolly, an Irish–speaking singer and harper from Co. Derry, travel through Ireland, Scotland, and Brittany to meet with other harpers, while Seamus O’Kane and I make the harp. I had met Seamus previously through our mutual interest in the bodhrán (the traditional Irish frame drum), and Seamus is rightly regarded as one of Ireland’s finest bodhrán players and makers. The rest of the team include Déaglán and Aoibheann Devlin, both enthusiastic and culturally–aware musicians, and Loic Jourdain, a fine artist in the field of film–making. It was their serious desire to attempt an authentic reproduction that held the greatest appeal for me.

I have been researching and making harps for many years (though not commercially), and in that time have often noted instruments which were said to be “replicas” of various surviving Irish harps. Although at first sight they appear impressive, on closer examination very few could fairly live up to this claim. Far too many of these instruments were not actual reproductions, but merely styled to look like the original. This may seem surprising, as one would expect a copy of an extant harp to be exactly that; but there is a real shortage of reliable and accurate information on many of the historic harps.

Seamus, Michael and Déaglán Devlin share a joke during the filming of “Banríon an Cheoil”.

(©2009 by Lugh Films, used by permission).

Yet if we are ever going to truly understand these instruments, we must first get beneath the superficial appearance to try to understand how they were actually constructed, and recreate their true acoustic and dynamic properties. Over the years, I have been able to closely examine a number of the other old harps, though not—until now—the Downhill. Yet of all the surviving harps it is the Downhill that we have the most background information about: its social and physical history, the man who played it and some of his music, and above all, the fact that it is the only harp for which we categorically know the tuning and gamut. For this reason, it is the sensible starting point for any broader study, and the benchmark to reference other work to. This is a key factor as to why the chance to take part in a project which focused on the Downhill Harp held special importance for me.

The rest of this article will concentrate on the harp itself and the process of building an authentic replica for the documentary.

There is a poem carved on the right side of the soundbox which states, “17 HUNDRED AND 02 I WAS FOUND BY C R KELY” and the last line says, “QUEEN OF MUSICK YU MAY CALL ME.” [8]

C. R. Kely is understood to be Cormac O’Kelly of Ballinascreen, Co. Derry, and it is from this poem that the documentary takes its title (Banríon an Cheoil means Queen of Music). Down the front of the forepillar the letters “C O DEVLIN” have also been carved, and it seems a reasonable assumption that this would have been the name of the harp’s original owner.

When Hempson was eighteen years of age, the harp was “found and bought” for him by three local benefactors (of Garvagh, Co. Derry): Counsellor Canning, Squire Gage, and Doctor Bacon.[9] Hempson seems to have kept this instrument throughout his life and it was said to be literally in his hands on his deathbed.[10] After the great harper’s demise it passed into the keeping of the Rev. Henry Harvey Bruce (Lord Bristol and Bishop of Derry) who had seen to Hempson’s welfare in his later years.[11] It remained with his family at Downhill, Co. Derry—hence its name—until the middle of the 20th century, when it was sold in an auction of Bruce family effects, and surfaced in a Dublin antiques shop in 1956.[12] It was finally purchased by Guinness in 1963[13] and today it can be seen on display at the Guinness Storehouse Museum in Dublin.

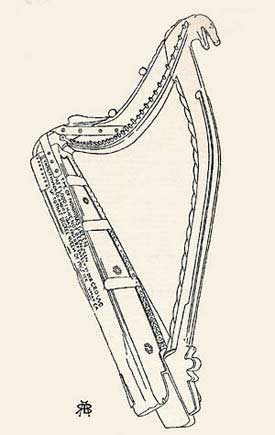

FIGURE 2. Drawing made by Robert Bruce Armstrong showing the condition of the Downhill Harp around 1900.

[You may click on the picture to view a larger–sized image]

As a preliminary measure, one of the producers made a visit to see the harp in Dublin and took several photographs. However, before attempting any serious reproduction of this unique instrument, it was essential to assess the information already known and available.

In 1904 Robert Bruce Armstrong published his seminal book, The Irish and Highland Harps, and to this day it remains the most important work on the subject. It contains a section on the Downhill Harp which gives a description, some key measurements, and a three–quarter–view drawing showing a general impression of its appearance (Figure 2).[14] However, this is not sufficient information to properly reconstruct this harp.

In 1997 Robert Evans wrote an article in The Galpin Society Journal [15] on the Downhill Harp which contained a general description and a few measurements, but not enough data for the purposes of replication.

In recent years a drawing has been produced purporting to show key information of the harp but giving no structural detail, and instruments built to this specification reveal significant discrepancies in string length, string positioning, and overall height from information given in the earlier published works or obtained from photographs.

Clearly there has been a dearth of reliable information available, and a fresh independent examination was essential if any serious attempt at a reproduction was to be made.

The producers made contact with the Guinness Storehouse Museum to see if it would be possible to view, measure, and film the instrument; and after several meetings Diageo, the current owners of Guinness, granted us permission, for which we are most grateful. The staff arranged for the harp to be removed from its display case, and kindly provided the team with a private area in which to examine it. My first reaction on seeing the harp and carrying it to the side room was that it is smaller and lighter in weight than I had expected. I suppose I had gotten the impression of a larger instrument from the engraving of Hempson playing this harp [see Figure 1 above]; yet it was now becoming clear that he must have been quite a small man by modern standards, and that the instrument was a more delicate and refined affair than I had imagined.

Nollaig Brolly, Seamus O’Kane and Michael Billinge, with the Downhill Harp at the Guinness Storehouse.

(Photo ©2008 by Loic Jourdain, used by permission.)

In the hours that followed, we got a good look at this instrument and carried out the normal surveying procedures of making sketches and taking extensive measurements and photographs. The producers had arranged for an archaeologist specialising in the analysis of tree–types to positively establish the identity of the timber the harp was made from, and this work was undertaken by a professional expert. The purpose of this was to confirm information previously put forward but about which some obscurity remained. In fact, it turned out to be accurate, but the absence of any existing report left us relying upon anecdotal evidence, and the only way to be absolutely certain was to commission an independent scientific analysis. The history of this is as follows.

In the letter written in 1805 after his visit to Hempson, Rev. Sampson stated that the harp was made of willow, with a back of fir, and it is likely that this information came from Hempson himself.[16] Willow is certainly what one would expect, as we know from historical references and empirical evidence of surviving harps that it was the preferred timber for soundboxes.

After Guinness bought the harp in 1963, they asked the National Museum of Ireland to examine it; the museum in turn consulted Maura Scannell, a highly–respected authority in their Natural History Division. She identified the wood as alder (which it indeed turned out to be) and our only reason for seeking a second study was that the report submitted by Ms. Scannell could not be found when we made enquiries seeking it.[17] Without knowing upon what basis this identification had been made, we could not determine the extent or method of analysis done forty–five years ago. This left nagging questions which could only be resolved by further scientific scrutiny, so a new test was undertaken to confirm the matter beyond doubt.

The analysis was quite simple, and involved taking a small scraping of wood which was then examined, on site, under a powerful microscope to identify its unique cell structure. The results proved conclusively that it is European alder (Alnus Glutinosa).

Having replaced the harp securely in its display case we had some remaining time, so in the afternoon it was arranged for the documentary team to visit the National Museum of Ireland at Collins Barracks and view some of the other surviving Irish harps. I had selected the FitzGerald Kildare Harp and the Mulagh Harp for Nollaig and Seamus to look at, and when we arrived these had been duly laid out for us on a table in the Conservation Department. The Kildare Harp is thought to have been made for the second son of the Earl of Kildare about thirty years before the Downhill was built and, as might be expected, it is a far more elaborate instrument, both in terms of its painted and carved decoration, and also its complex soundbox design. On the other hand, the Mulagh Harp, which probably dates from around the mid–18th century, is simpler than the Downhill, with less decoration and a more rugged soundbox. I specifically chose these two harps as I thought they might provide the right degree of contrast and enable the Downhill to be viewed within a broader context.[18]

The Downhill Harp can be said to consist of two main components, the soundbox and the frame.

The soundbox, as is the norm with all but a few later exceptions,[19] is hollowed out of a single block of wood from the back and right through to the top, with a separate back–board being fitted afterwards. The soundboard (or belly) of this instrument is not flat, as has often been incorrectly assumed, but was deliberately carved to form a lateral arch (i.e., across as opposed to lengthways). Curving it in this way and hollowing the box as described above will affect both the way the board flexes and the “Helmholtz” resonance of the body itself—a simpler box form would not sound the same.

Although this manner of construction takes far more time and effort than simply scooping out a flat–boarded box, there is obviously merit to it, as most Irish harps from the 17th and 18th centuries are made in this more complex form. Another feature requiring extra work is that the panels in the sides and face of the soundbox are carved and recessed, and framed by stock–cut beading.

The frame is comprised of the neck and forepillar, each being formed from single pieces of timber. There is quite a lot of carving involved, not just for the decoration but also in the neck and pillar, as these vary in thickness and section. The neck is fitted into the forepillar with a mortice and tenon joint which in this case is—somewhat unusually—dowel–pinned as well. The frame is slotted into the soundbox, with the tenon at the bottom of the forepillar fitting into the mortice in the projecting block at the base of the box. The large tenon at the shoulder locates into the top of the box like a cork in a bottle.

Wherever you look on the harp you can see marks left by the edge–tools that Cormac used, with no real attempt having been made to remove these by sanding or scraping, either on the inside or the outside. I got the impression that he worked quickly but with confidence, and was quite familiar with the way that alder behaved, and that he had probably used it many times before for other carpentry.[20]

As mentioned earlier, discrepancies were found among the sources cited above, and I was curious to know how these compared with our own results. The survey showed Armstrong’s work to be the closest (even though he probably had not seen the harp himself, and got the number of tuning pins and string shoes reversed).

We measured the box as being slightly narrower in the treble and a little wider in the bass than stated by Evans (the thickness shown for the soundbox is clearly a misprint).[21]

The other source referred to earlier gives an overall size that was found to be two inches too big, with its strings being in error (length and position) by as much as an inch.

For the record, the main dimensions of the Downhill Harp as given by Armstrong, with which our survey agreed, are as follows:

Ninety–odd years spent in the hands of a travelling musician, particularly on 18th–century roads, will take a lot out of any instrument; and when this harp was bought in 1963 it was in a sorry state. The back was lost, it had suffered greatly from woodworm, and it bore numerous cracks, splits, and scars of wear and tear.

The Downhill Harp ready for inspection at the Guinness Storehouse, as Loic Jourdain (the Director) checks a camera setting.

Photograph of the Downhill Harp by Permission of Guinness Archive, Guinness Storehouse. (Photo ©2008 by Michael Billinge.)

[You may click on the picture to view a larger–sized image]

Since Guinness became its owners, restoration and repair work has been carried out which includes the fitting of a new back; the gluing together of the two parts of the broken neck; the addition of a centre–strip (not an original part of the design) which was glued inside the box to reinforce the area of a major split that had formed along the line of string holes; and the application of filler and colour to hide many of the dents, gouges, wormholes, and gaps in the surface. The colour of the harp today is much darker than it would have been when first made, and there is evidence to suggest that it has had additional “finishes”—varnish or staining—applied on at least three occasions. Brass wires have also been added for visual effect.

These modern repairs make it more difficult to examine the harp in minute detail, but they have also helped to strengthen and stabilise its structure, so perhaps one shouldn’t complain. However, it is probable that most, if not all, of the other physical damage and repairs took place during Hempson’s life.

The most obvious damage is that the neck had broken clean through and then been repaired by affixing iron plates to either side with large screws.[23] There was also an iron strip added across the top of the neck and down onto both sides of the soundbox, but other than holding the neck into the box, there seems no other obvious purpose for it.[24] It is possible that this ironwork was added after Hempson’s time, as none of it appears on the engraving made from the drawing of him done in 1797 by E. Scriven; but, since other details of the neck are also not shown, this is inconclusive. However, this sort of major structural failure to the neck is most likely to have resulted from the harp receiving a violent blow, such as being dropped, while under tension; therefore it probably happened during its playing life.[25]

The Scriven engraving does show the metal reinforcements which were added to the soundbox after it had suffered several serious splits and cracks. Such fissures are often the result of stresses produced within the box by a combination of string tension and the natural ageing process, and any physical shock would clearly exacerbate the situation. The metalwork consisted of three thin straps positioned across the soundboard, and a copper plate nailed across the back of the box at the top (there was also a copper plate on the inside at the bottom). At some stage prior to 1962, these reinforcements were removed and three tuning pins also went missing.[26]

Other damage to the soundbox includes a piece broken off the top right corner and heavy abrasion to the left side at the bottom (probably caused by Hempson’s boot). In addition, the bottom right side may have suffered even greater wear, as an oak patch has been set in. This would be consistent with a playing position where the harp is angled slightly to the left, and the right boot would then exert more pressure on the back edge; but it is also possible that the oak insert was intended to repair some other physical damage beyond simple wear, such as a piece being knocked out.

One thing missing from the engraving of Hempson is the harp’s animal head, which appears to be a serpent or some mythical creature.[27] Armstrong thought that the artist might have omitted it on account of the size of the canvas, but this is hardly credible. It is clear from looking at the actual harp that at some time during its life the head was separate from it, so I see no reason to doubt Scriven’s depiction.

This presents three options. The first is that the head was not part of the original harp but added after Hempson’s death. The second is that it was originally carved as part of the forepillar and later broke off as the result of some mishap, but that Hempson kept the head (the grain of the timber runs in the right direction for this to be possible). The third is that when Cormac made the harp he carved the head as a separate piece, attaching it to the forepillar afterwards, and that it was subsequently removed (either deliberately or accidentally) but kept and reattached later. An analysis of the visual evidence leads me to favour the third option, but the area surrounding the join of the head and pillar is currently obscured by filler, and this makes any conclusive assessment difficult. This is something I hope to investigate further. For the reproduction we decided to make the head integral with the forepillar.

Plotting out the measurement and survey details to produce a full–size drawing is not only vitally important, it is standard correct procedure. In addition to producing a blueprint to work from, it provides a necessary check to reveal any mistakes or discrepancies in the survey work and confirm that sufficient information has been taken in the first place. Without a complete and reliable survey, one cannot be confident that full accuracy has been achieved.

Drawing out the work can also help with understanding the instrument, revealing things that are not immediately apparent from simply looking at it. An example of this is the unusual way in which Cormac laid out his harmonic curve. To give a more even string spacing, he varied the distance between the tuning pins, increasing it as it goes down into the bass. There is nothing unusual in this, but instead of an even change across the range, as might normally be expected, he seems to have done this in a series of blocks or groupings. It appears as though he only worked out the placement of certain strings, and then positioned the others evenly between these. This is unusual, and not immediately noticeable to the casual observer.[28]

The drawing was also a great aid in determining the most likely string layout. As is the case with several of the other old harps, the Downhill has a greater number of string holes in its soundbox than there are tuning pins in the neck (it has thirty–two shoes and only thirty pins). This in theory offers three different ways of stringing. However, in drawing out these options it soon became apparent that the middle one (top string to the second highest shoe, etc.) was likely to have been Cormac’s intention when he laid out this instrument. Stringing the harp with either of the other alternatives produces an unnatural and pronounced variation in the angle of the strings, whereas in the centre distribution the angle appears far more consistent and sensible.[29]

One thing that was apparent from the original soundbox is that Cormac chose a good–quality straight–grained piece of timber, free from imperfections. We knew that obtaining alder of equal calibre would not be so easy in today’s very different environment, as the block had to be both large and unblemished. While we were attempting to locate a suitable section of alder, I also had in my possession a nice piece of willow that I had been keeping for another harp project, which could do as a reserve if usable alder could not be found (bearing in mind willow’s favourable qualities as harp timber, and Sampson’s comments implying that Hempson himself thought his harp was willow).[30]

Because the project involved scooping out the soundbox from a single block of wood, it meant we had to source the timber ourselves (European alder of the size and quality required is not available commercially here). After some searching, a large alder tree was located, and from the outside the trunk looked fine; but once it was opened, a closer inspection revealed it to be far short of the standard we needed. This was disappointing, as high–quality timber was—and is—a prerequisite for any skilled harp maker when selecting his material. There did appear to be enough good alder to allow us to cut the irregular shapes of the neck and pillar, but for the soundbox we were obliged to use the willow.

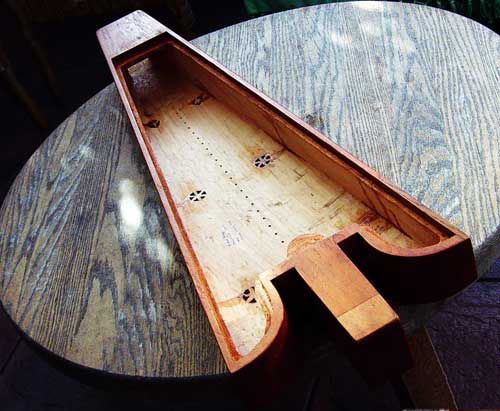

The new soundbox complete just before finish applied. (Photograph ©2009 by Michael Billinge, used by permission.)

[You may click on the picture to view a larger size image.]

I first made a clarsach with a hollowed–out soundbox back in 1977, so many of the initial procedures have long been familiar to me. The primary stage was to rough out the basic block shape, ensuring that it was sufficiently over the stipulated size to give some leeway for adjustment if necessary. I like to work inwards, towards the desired shape, rather than simply cutting out the final form straight away, because this allows at least a chance to readjust the position if any hidden “nasties”—blind knots, checks, splits, etc.—are discovered, though it’s by no means a safeguard against them because they can be unpredictable. (This was one problem with trying to use the alder we had sawn, which had many such flaws, not visible externally.) There is normally a differential in the moisture content in a large block of wood, even if it has been seasoned for years, so there is always likely to be some movement as it dries and shifts. It is therefore best to first do a rough hollowing, removing the bulk of the timber, and then put it aside for awhile to dry further. The extra thickness can be shaped down after the wood has stabilized.

Inside view of the finished soundbox of the Downhill Harp reproduction, showing how the top of the box is hollowed right through. (Photograph ©2009 by Michael Billinge, used by permission.)

[You may click on the picture to view a larger–sized image]

My intention was to make the box with the same type of hand tools that Cormac would have used, but holes were done with an electric drill. For the rough hollowing I “stitched–drilled” a row of holes around the perimeter of the cavity, plus a few lines of them across the box (though one must not go too deep). This physically demarcates a safe area within which more aggressive removal techniques can then be used: a claw–hammer and a masonry chisel proved effective at rapidly taking away quite large chunks of timber.

After the box had been left to further dry for some weeks, work could start in earnest, this time using the sort of extremely sharp edge–tools that Cormac would have had. The first task was to shape the outside of the block into the correct “silhouette.” For this, a 15–inch plane was used to square up the sides and face, with chisels for carving the distinctive curved lobes of the bottom end.

To construct the arched soundboard, I adopted a method of planing a series of flat strips along the board, tangential to the curve. Successive strips were then planed, each one bisecting the last to remove the ridge, and getting progressively smaller. The very last ridges were so small that they were virtually invisible, so I had to rely on touch, skimming them with my fingers until I was satisfied that the surface was correct.

Using an improvised “scratch–stock” to cut grooves as a depth guide prior to finishing the face of the soundbox. (Photograph ©2009 by Michael Billinge, used by permission.)

[You may click on the picture to view a larger–sized image]

Before the inside could be finished, the hole in the top of the box (into which the neck fits) had to be made, which didn’t require anything too complicated or technical, being merely a matter of drilling a few holes through to get started, and disposing of the remaining wood with a chisel. After this was completed, the inside of the box could then be carved back to the desired position using various chisels and gouges. This was a labour–intensive process which required great care (similar to the shaping of a ’cello back, though it doesn’t need quite the same degree of accuracy) and I found getting into some parts of the box awkward. I made an improvised thickness gauge to ensure that the right amount of wood was removed, allowing for the fact that the outside surface of the box had yet to be cut back.

FIGURE 3. The new soundbox just before the finish was applied

(Photograph ©2009 by Michael Billinge, used by permission.)

[You may click on the picture to view a larger–sized image]

The face of the soundboard and external sides of the box were carved down, leaving a raised central string band standing proud, with beaded edges framing the recessed panels on the sides, and decorative features on the front (Figure 3, above). The surfaces were cut back with a sharp shallow gouge, but only after a scratch–stock had been used to make a series of grooves as a depth guide. I then fashioned a shaped scratch–stock to form the beaded edging (see photo).

All that remained to finish the box was to drill the string holes, carefully carve out the six decorative sound holes with their hexafoil petal–shapes, and cut a rebate into the rear of the box to take the back panel.

The back of the original soundbox disappeared long ago, so a plausible form of replacement had to be considered, and I chose to use a softwood rather than a hardwood for two reasons. The first was the reference in the Sampson letter to the back of the Downhill being made of fir,[31] and the second was that the few original backs that survive on the Carolan, Mulagh, and Sirr Harps (all roughly contemporary with the Downhill) were made of softwood as well. I also used these harps as a guide when deciding the shape of the access holes to be cut into the back panel.

While I was down in Cork constructing the soundbox, Seamus had been busy at the other end of the land making the frame and some of the metalwork. When this was completed, I travelled up to Derry in order to do an initial fitting–together of the two sections, after which I brought them back home for further work.

Technically, the frame is not difficult, but since both the neck and the forepillar had to be shaped down from pieces of solid wood three inches thick, and both required ornate carving, it did involve a lot of work. Apart from the basic shape, there are also the other features—the open–mouthed head, the beaded ridge along the top of the neck with its strange cylindrical projections, and the “rope–work” down the back of the pillar (though this feature is more deeply carved than that descriptive term implies). The front face of the pillar is also recessed behind a scratch–stock cut beaded edging.

A closeup view of the brass string band of the Downhill Harp reveals a join. For a close-up image of the join, please click on the image. See also footnote 32.

Photograph of the Downhill Harp, by permission of Guinness Archive, Guinness Storehouse

(Photo ©2008 Michael Billinge, used by permission.)

[You may click on the image to view a large–size image.]

The neck bands or plates through which the tuning pins pass are made from pieces of brass.[32] I think it most likely that the originals were sawn and filed from a flat sheet, but part of the purpose of this documentary was to investigate possible construction methods of the period, and Seamus wondered if these brass fittings might have been formed by bending them from straight strips, i.e., whether they were “wrought” rather than cut. Never being one to sidestep a challenge, he duly made these bands up by repeatedly heating, bending and hammering strips of brass into shape.

The shoes surrounding each string hole are fastened on with tiny nails, and their purpose is to prevent the wire cutting into the soft wood of the board. These are made of very thin brass, roughly triangular in shape, and Seamus had a stamp made (rather like a cookie–cutter) in order to punch them out of the sheet. It is probable that the originals were cut out individually because they are not all exactly identical, but using a stamp would have been an obvious alternative in the early 18th century, and it certainly proved to be an effective method for us. The shoe that has been fitted to the uppermost string hole on the original harp is different, however: it was made from a short length of brass rod bent into a horseshoe shape, with the ends hammered flat and pierced to house two small nails. As suggested above, the top string hole was probably not actually used, and the shoe added merely for visual purposes.

It was originally arranged that a third party would make the brass tuning pins for us, but when they arrived we found that they were neither manufactured to the requisite specification, nor of good quality, so we decided to look elsewhere. This left us in difficulties because we had a television production deadline to meet and were under time–pressure. After some searching, I then made contact with Daniel Speer of Argent Fox, who was able to supply high–quality brass pins to the length and diameter we required, and ship them to Ireland in time. By this stage, the tuning pins were the only thing we needed to complete this instrument, and the date of the concert was getting too close for comfort; so you can imagine my relief when these arrived and I found them to be first–rate. We now had all the components of the harp.

Preparing the fitting of the frame and box, Seamus, Déaglán and Michael.

(Photo ©2009 Lugh Films, used by permission).

The final fitting and adjusting of the frame and box, as well as the positioning, attaching, and drilling of the metal bands and pin holes, had to be done with great care, which meant constantly checking to ensure that string lengths and positions were in agreement with the original. Then, just before the metalwork was attached, the woodwork needed to be given its finish. It’s difficult to know exactly what Cormac might have used in 1702, and I considered various varnish mixtures before deciding that an oil finish would be a highly plausible option. I added a little stain to bring the willow and alder into harmony, and closer to what might have been the original colour (the harp has been darkened in the intervening centuries).

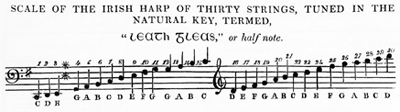

Tuning for the Downhill Harp from Bunting.

[Please click on the picture to view a larger–sized image]

Edward Bunting noted down the tuning of the Downhill Harp from Hempson.[33] This is one of the things that makes the Downhill especially important: it is the only existing old Irish harp that we categorically know the gamut and tuning for.

FIGURE 4. The Downhill Harp reproduction finished and strung for the first time.

(Photograph ©2009 by Michael Billinge, used by permission.)

[You may click on the picture to view a larger–sized image]

Historical references for Irish harps’ wire strings speak of brass (though perhaps copper alloy would be a more accurate term), and sometimes cite iron or steel in the treble. But it is not until the second half of the 19th century that any information as to the diameter of the strings was recorded. The problem is that the harps these gauges refer to were of a different era from the Downhill, being made nearly a century and a half later, and of totally different construction, with longer strings and “Grecian” (pedal harp) type soundboxes.[34] Therefore, drawing direct comparisons is not necessarily relevant and should be approached with caution. We only have to consider just how much the gauges of gut harp strings changed from the mid–18th to the mid–19th century to realise the dangers of generalising or jumping to conclusions. It is likely that then, as now, different harpers would use gauges according to their personal preferences, in the same manner as modern guitarists who buy sets of strings in different weights.

As regards obtaining suitable wire in the early 18th century, an obvious source for this was harpsichord suppliers. The string lengths on the Downhill are not so great as to require iron in the treble, so I decided to use period harpsichord brass (supplied by Malcolm Rose of Lewes in Sussex, England). Beyond that, it is a matter of ongoing experimentation. My initial attempts utilised yellow and red brass wire between the gauges of 0.014 and 0.046 of an inch, and the results proved most encouraging.

When it was strung (Figure 4), I was amazed at just how quickly this new harp settled in, and its initial tuning–up and first notes were captured by the film’s sound crew. Wire–strung harps can be a bit sensitive, but this one went into tune almost immediately, with no “chasing around” of pitches as the board adjusted to being put under tension, and its voice rang from the start–rich, clear, and resonant. This only underlines what a beautifully–balanced instrument the Downhill Harp is.

Indeed, “Queen of Music” is a fitting title for it, and I am proud to have had a hand in bringing to life this reproduction of a national treasure.

To learn more about the Downhill Harp, and especially about the inscription carved on the instrument, please visit the Appendix 1 to this article.

Michael Billinge has been researching historical harps for many years, and made his first wire–strung instrument in 1972. Further harps followed, including an ornately–carved clarsach with a soundbox hollowed out of a single block of willow.

In 1981 he turned his attention to the enigmatic Dalway Harp Fragments (now also known as the Cloyne Harp) and through this research presented a case for the existence of an early chromatic Irish harp, demonstrating how the 1621 Dalway Harp could be interpreted as an example of this. An article based on this work was published in the May 1987 edition of the British journal Early Music, co–authored with harpist Bonnie Shaljean.

More recently he has been examining many of the historic harps in the National Museum of Ireland, and taken part in the aforementioned building of the Downhill Harp reproduction.

I am grateful to Diageo, the owners of Guinness, for allowing us access to the harp and to Eibhlin Roche, Guinness Archivist, for her help; to The National Museum of Ireland, for their time and assistance; to Lugh Films and Gallan Films; to Loic Jourdain, Anne Marie Rogers, Déaglán and Aoibheann Devlin, and not least, Seamus O’Kane, for having the vision and desire to bring this project about.

Website for Lugh Films

Website for Guinness Storehouse

[1]

Edward Bunting, A General Collection of the Ancient Irish Music, London, 1796.

Edward Bunting, A General Collection of the Ancient Music of Ireland, London, 1809.

Edward Bunting, The Ancient Music of Ireland, Dublin, 1840.

Please visit our Library to find these and other books.

Bunting’s papers are preserved in the Library of Queen’s University, Belfast. For a catalogue and thematic index for this material, see: Colette Moloney, The Irish Music Manuscripts of Edward Bunting, Dublin, 2000.

[2] Edward Bunting in his volumes of 1809 and 1840 refers to “Hempson” and this is also the form of the name he uses in his notebooks. Following the publication of Bunting’s 1840 work the name “Hempson” is the one most commonly found in subsequent publications. However, prior to this date it is the name Hampson and Hampsey that is generally to be met with.

[3] The letter by the Rev. George Sampson was written to Sydney Owenson (Lady Morgan) concerning his interview with “Hampson” undertaken the previous day, 2nd July 1805. We are fortunate that she chose to include this letter in her epistolary novel of 1806, The Wild Irish Girl, Vol. 3, letter XXVII, for without this letter our knowledge of Hampson would be greatly diminished. [For the text of this letter see Sampson’s letter to Sydney Owenson.]

[4]

Bunting, 1840 (op.cit.), pp.73–76.

Bunting has missed out five sentences, mostly concerning Hempson’s acquaintance with Sampson’s family, but he has also made a few alterations to the wording and details. For this reason Sampson’s actual letter should always be referred to as the primary source.

[For a further exploration of this see Sampson’s letter regarding Hempson.]

[5] Bunting, 1840 (op.cit.), p.73.

[6] See, for example, the opening line of Sampson’s letter (op.cit.), p. 78.

[7] See, for example, Bunting’s papers (op.cit.), MS 29/182 (or Moloney (op.cit.), p. 354).

[8] This verse has often been quoted before, unfortunately not always accurately, and may have been the origin of the misguided belief that the old Irish harps were made out of wood that had lain buried in a bog for centuries or millennia. [For a fuller description and investigation of this poem see the Appendix 1.]

[9] Sampson’s letter (op.cit.), p. 78–79.

[10] This is if we are to believe Bunting who, writing over thirty years after the event, gives the following poetic, account of Hempson’s death:

The day before his death, upon hearing that this gentleman [Rev. Sir H. Harvey Bruce] had come to his cabin, he desired to be raised up in bed, and the harp be placed in his hands. Having struck some notes of a favourite strain, he sunk back unable to proceed, taking his last adieu of an instrument which had been his companion, even in his sleeping hours, and was his hourly solace through a life protracted to the longest span.

[Bunting, 1840 (op.cit), p. 76.]

However, Bunting appears to have somewhat over–dramatised his description and even altered a few facts, for earlier accounts provide us with a more objective narrative. The following was in print just a few months after Hampson’s death:

“A few hours before his death he tuned his harp in order to have it in readiness to entertain Sir H. Bruce’s family, who were expected to pass that way in a few days, and who were in the habit of stopping to hear his music. Shortly after, however, he felt the approach of death, and calling his family round him, he resigned his breath without a struggle, being in perfect possession of his faculties to the last moment.” [The Monthly Magazine, April 1, 1808, p.112.]

Almost identical versions to this one are related over the next few decades (e.g. see Richard Ryan’s, Biographia Hibernia — A Biographical Dictionary of the Worthies Of Ireland, 1821, vol.2, p.305, and William Hone, The Every–day Book, vol.1, p.40.)

Note. If the above account from the monthly magazine is correct, it also gives us an insight into Hempson’s abilities at the end of his life. He is clearly still capable of playing the harp but is not doing it regularly enough for the instrument to stay fully in tune; thus it needed to be pre–tuned some days before he performed on it.

[11] Sampson’s letter (op.cit.), p. 84, & Bunting, 1840 (op.cit.), p.76.

[12] Memo to Lord Moyne from V. M. Anderson, 3rd December 1956 (Guinness Archive, file GDB/CO04.04/0014). Also communication from L. A. Luke to Dr. C. K. Mill, 22nd January 1963 (Guinness Archive, file GDB/CO04.04/0014) relating that Mr. O’Connor (the antiques dealer) had said he had acquired it at an auction of the effects of the Bruce family at Downhill several years previously.

[13] G.P.S.C. Minute dated 24.1.63, indicates that the Board approved “the purchase of the Downhill Harp...for the sum of £350” (Guinness Archive — file GDB/CO04.04/0014).

[14] Robert Bruce Armstrong, Musical Instruments Part 1, The Irish and Highland Harps, 1904. pp. 88–91.

[15] Robert Evans, A Copy of the Downhill Harp, Galpin Society Journal, Vol. 50, March 1997, pp. 119–126.

[16] Sampson’s letter (op.cit.), p. 85.

[17] The report is mentioned in a letter dated 24th April 1963 from William O’Sullivan (Keeper, Art and Industrial Division) to Leslie Luke Esq. of Guinness (Guinness Archive, file GDB/CO04.04/0014) but the whereabouts of this report, or whether it even still exists, is not presently known. The letter states: “She [Maura Scannell] identified the wood as Alder (Alnus) all through on the soundbox, forepillar and harmonic curve.”

[18] Regrettably, restraints imposed by the broadcast time limit meant that the scene filmed at the National Museum of Ireland was not included in the final edit of the documentary. This article was originally written several months before the documentary was first broadcast (3rd May 2010).

[19] That the soundboxes of the older Irish harps were hollowed out from a single block of wood is well attested. However, by the 18th century this practice was by no means universal, and makers also adopted a method of constructing the soundbox out of several pieces of wood. During the 18th century it is likely that there were many more harps made with constructed soundboxes than is generally appreciated.

[20] Although European alder (alnus glutinosa) might seem to be an uncommon timber for general wood–working practices, there was a time when it was in use in Ireland and Scotland for the making of furniture. It even acquired the nickname of “Scottish Mahogany” See Grieve, M., A Modern Herbal, vol. 1, 1931, “Alder”; and Robinson, M., Concise Scots Dictionary, E.U.P. 1999, “Scotch mahogany”; also see Appendix 1 for a further commentary on Alder.

If you linked here from the Appendix 1, please use this link to return.

[21] Robert Evans (op.cit.), p. 119, gave the following figures:

Width box treble = 11cm.

Width box bass = 29.5cm.

Thickness soundbox = 2.8cm.

[22] This measurement is the longest possible string length, but it seems more likely that the lowest string would have been strung to the next string shoe up the box. This would give the slightly shorter working string length of about 95 cms. See comments associated with note (29).

[23] Someone looking at the harp today would have little idea that the neck had at one time split into two separate pieces. Yet even after the iron plates were added to strap it back together, the gap between the two parts was still large enough for Armstrong to record on his sketch [fig. 2] and it is also clearly visible on the few photographs of the harp which were taken prior to the later repair of 1963.

[24] That the purpose of this strap was to hold the neck into the soundbox may at first seem strange, for one might expect that the tension of the strings pulling down on the neck would do this. However, this is not to appreciate the way that the forces act on this joint. For although the main action of the force is to pull the two parts together, the force isn’t pulling through the joint but in front of it, thus there is a leverage effect with the front of the joint acting as the fulcrum. As the neck in front of the joint tends to be pulled down the back of the joint tends to lift up. If the neck is strong and stiff enough this movement is negligible, and would not require any remedial action. However, once the structural integrity of the neck has been compromised, as is clearly the case when the neck is broken and patched as the Downhill’s was, then such a strap becomes necessary to prevent excessive movement.

There are other harps that have used a metal strap to hold the end of the neck into the soundbox, for example those on the “Queen Mary” and the Mulagh (although this, along with most of the other metalwork, was later removed from the latter).

[25] The suggestion that the neck was broken and repaired while still in Hempson’s possession is reinforced by Sampson’s observation upon his visit to Hempson that the harp was “patched with copper and iron plates.” That is, that these iron plates were in situ in 1805.

[26] The use of thin metal straps placed across a cracked soundboard, in order to prevent the crack from opening up, can be found on a number of other harps that had suffered similar damage in the 18th century (two good examples can be seen with the FitzGerald–Kildare and O’Ffogerty harps). On the less acoustically important areas of the harp, such as at the ends of the soundbox and the instruments frame, more substantial metal plates and strips could be used. Iron, brass and copper have been utilised on many of the repaired harps, and though copper would have been the weakest of the metals it is also the easiest to form into shape and simplest to work with.

[27] The most likely candidate for a “mythical beast” would be an aquatic monster often known in Ireland as a Péist or Péiste [also Phéist and Payshta], a name thought to have derived from the Latin pestis (for pest). This serpentine creature had a body resembling an eel but a head more like that of a horse, with an undulating mane down its back. One of the earliest printed accounts of this beast is be found in Crofton Crocker’s Fairy Legends and Traditions of the South of Ireland (c.1825, originally published anonymously). Here, in the story of “Linn–na–Payshtha”, it sits as guardian to an ancient treasure. Crocker describes it thus: “...the Payshtha was there afore him, lying like a great big conger eel, seven yards long, and as thick as a bull in the body, with a mane upon his neck like a horse...” Similar creatures also occur in legends outside of Ireland, one of the best–known being the “Lambton Worm” which inhabited the river Wear in northeast England. It seems quite likely that Cormac took a local “Péist” legend as an inspiration for the carving on this harp.

[28] For a better idea of how these groupings are formed the following measurements should give an indication of how the distance between the tuning pins only changed in blocks. Number 1 is the highest tuning pin in the treble and number 30 the lowest pin in the bass and the distances are centre to centre of adjacent pins:

01 — 14 = 12½ mm (½ inch)

14 — 18 = 15mm (⅝ inch)

18 — 21 = 20mm (¾ inch)

21 — 24 = 25mm (1 inch)

24 — 26 = 31mm (1¼ inch)

26 — 29 = 35mm (1⅜ inch)

29 — 30 = 39mm (1½ inch)

[29] The following will give an idea of the degree of deviation from the parallel produced by the three theoretical options. With the middle (the most likely) option the alignment of the strings deviates by less than one degree from the highest to the lowest string. However, using either of the other two possibilities produced a deviation in the angle of the strings by six degrees or more. (Note. These angles apply to the harp in its original state, as designed; in later life when the board lifted, broke, and was strapped together the string angles would not have been so consistent.)

[30] Sampson’s letter (op.cit.), p. 85.

[31] Sampson’s letter (op.cit.) … ibid.

[32] Contrary to Armstrong’s observation (op.cit., p. 89) that the “metal bands through which the tuning pins pass form single curves”, they are in fact assembled from three separate pieces. Each band consists of a short section at the treble end (which takes the form of a petal–shaped decorative piece), a middle section which covers the majority of the harmonic curve, and the last part in the bass. On the left hand band the lower section is joined between the 5th and 6th tuning pin up from the bass, whereas on the right it is between the 4th and 5th. The pieces are attached with carefully crafted overlapping recessed scarfed joints, each held together with two small brass rivets. The most probable reason for adopting what might seem a very elaborate method of construction would be to save on material costs. Constructing the bands in this way meant that the pieces could be cut out from a far smaller sheet of brass than would be necessary to cut them whole. Even though this method required more work, the probable saving in material cost would have made it worthwhile. The Downhill harp is by no means unique in having its tuning pin bands constructed from several pieces, for this can also be observed on several of the other harps.

[33] Bunting’s manuscripts (Ms. 29, page bearing the number 153, annotated “Hempsons Harp 1702”). Bunting also printed this on page 23 of his 1840 volume.

[34] It is clear from the description that Armstrong gave of his Egan made “Society Harp” (see The Irish and Highland Harps, p. 106) that Egan was using a similar method to construct these soundboxes as he used for his pedal harps. However, any suggestion that he was merely making use of an excess of pedal harp boxes is quite wrong, for the width of the box given by Armstrong is much wider than that used by Egan, Erard and other makers in the construction of their “Grecian” style pedal harps. What is apparent is that Egan considered the soundboxes of his wire–strung instruments to be worthy of the same degree of workmanship as those of his expensive pedal harps. But without the constraint of having to conform to the size of a pedal box he was clearly free to redesign these boxes and utilise a greater width.

Michael Billinge © 2011

Ireland

Submitted to this site on 14 May, 2011

Except where otherwise noted, content on this site is licensed under a Creative Commons License.

Permissions beyond the scope of this license may be available by contacting us at editor@wirestrungharp.com.